| M100 Cam angle sensor cheap fix |

Brent Wright <brentw1@scruznet.com>

Well, My cam angle sensor finally failed sufficiently to cause the engine check light to come on etc. The thing actually contains two sensors, one the cam angle and another one that produces the "41" error, the second sensor appears to be a hall effect part that produces one pulse per cam rotation, the shop manual says it is used for RPM sensing below a certain rpm. In any event I called bean and they said the part from lotus was 250$ this seems outrageous, I called Izuzu and they wanted 110$ for the same part. This seemed expensive also , ok so I am cheap.

Anyway I didn't want to re-time the sensor assembly and the cam angle part was not the problem, So I removed the rpm sensor ( the lower sensor) and went looking for a GM replacement for just the defective sensor. I spent a fair amount of time and found similar units but none with the correct mounting. However I did find cheap replacements for the angle sensor component.

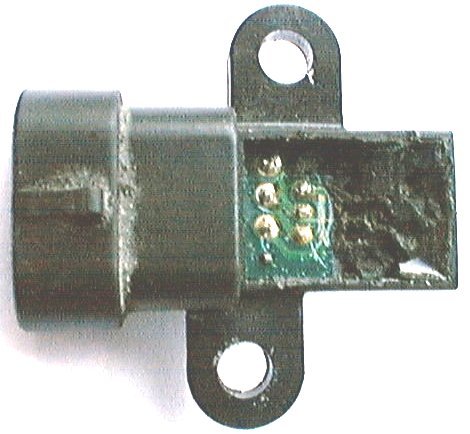

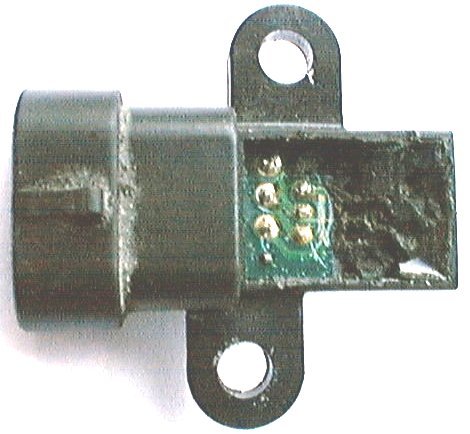

So I figured I had nothing else to loose and hall effect devices should be reliable I thought it might be a internal connection. I cut away the potting compound from the back of the sensor to expose the printed circuit for inspection.

What I found was the printed circuit only extends 1/3 of the way up from the connector the rest of the sensor assembly appears to house just the magnets. After exposing the circuit board back you could clearly see the failure of the solder connection to the connector on the printed circuit board, the sensor appears to only have one component the hall sensor and the board just wires the three wires from the sensor to the connector. The fourth connector pin is not used.

I re-soldered the connectors and remeasured the pin end of the connector with my ohm meter and everything appeared to be connected now. The solder failure doesn't appear to be a bad solder job it looks like it failed from either mechanical or thermal stress. To reinstall the sensor, You will need to align the sensor up and down , it has a fair amount of play, to center the slot in the sensor with the interrupter, DO THIS BEFORE YOU TURN THE MOTOR or you will probably trash the whole sensor. I pushed the car in gear to rotate the interrupter slowly and aligned the sensor.

The repair seems to have been a success. It idles as it should now and the check engine light has stopped coming on.

Just a note: I unhooked the NEGATIVE lead on the battery to reset the errors and unfortunately the learned mixture map in the control module so I could detect any new faults and so far it has been fine.

If anyone tries this fix and has any problems with it let me know.

Brent

Enclosed jpeg of sensor, mine has been working fine for 3 years now.