This is the mold used to form the bottom of the Elan. You can see how the body wraps around and over the shock towers.

| Manufacturing an Elan Body |

The following are Lotus factory photos of the manufacturing process Lotus used for the Elan. Photos are the courtesy of Mike Ostrov's Historical Lotus Collection.

The following photographs were distributed by Lotus Cars in the early 60's just as the Elan began production. Click on the photo to enlarge.

FIG 1

This is the mold used to form the bottom of the Elan. You can see how the body wraps around and over the shock towers.

FIG 2

This is a photo of the mold for the upper half of the body. Note how segments of the mold are bolted together. The technicians are

prepping the mold for the layup of glass and resin.

FIG 3

Here is the mold for the upper half of the body. It is easy to see the segmentation of the mold and the jig that

holds the mold in the correct position. Note that the jig is attached to a "spit" that allows the mold to be rotated.

FIG 4

Here a technician is laying the glass fiber and resin. Obviously safety precautions were lax, before worker safety had become

an issue in the workplace.

FIG 5

Once the fiberglass composite has hardened the mold is removed. The body remains on the "spit" and awaits the removal of the

excess fiberglass.

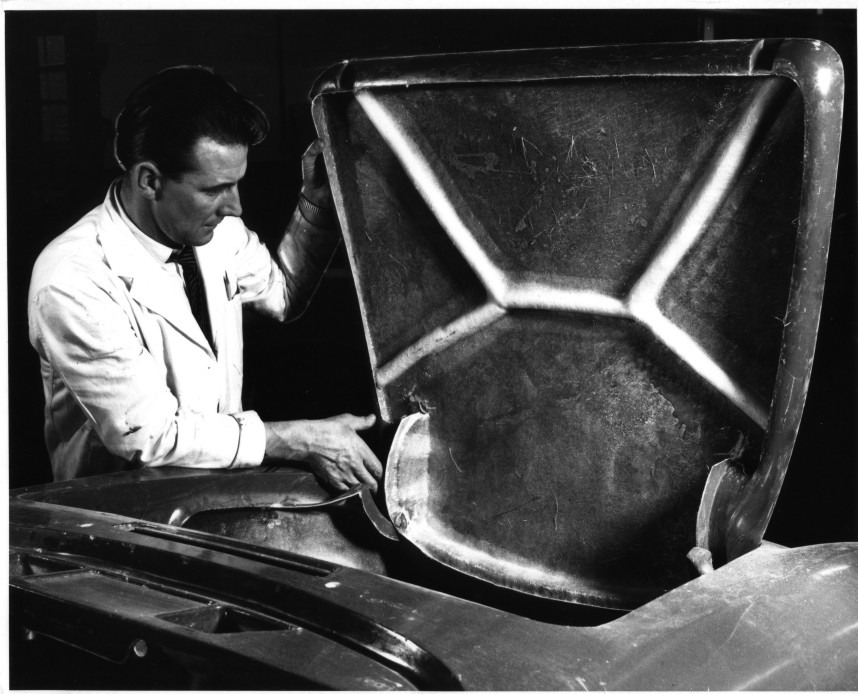

FIG 6

The bottom half of the body is being fitted to the top half.

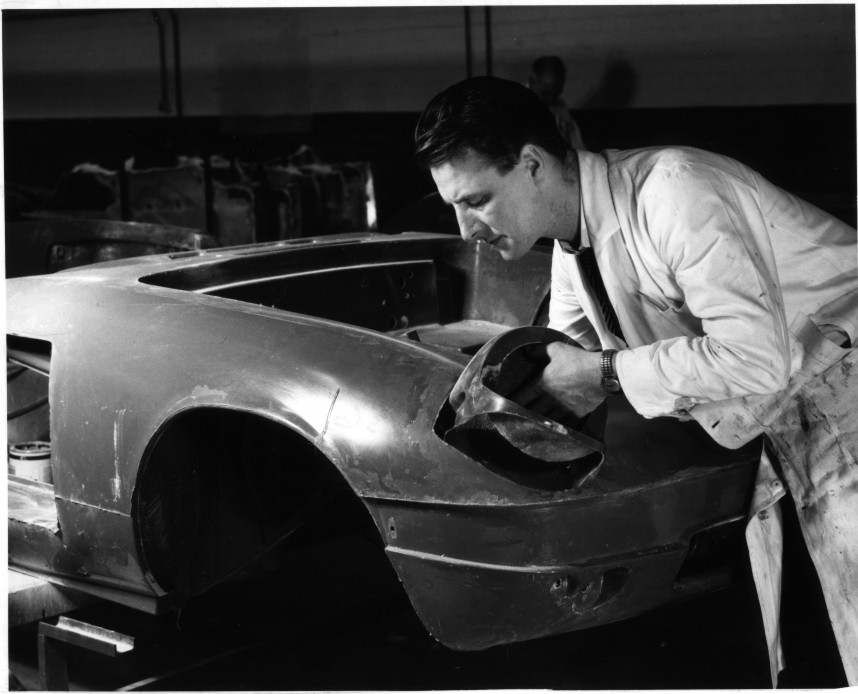

FIG 7

The Bonnet is fitted to the body.

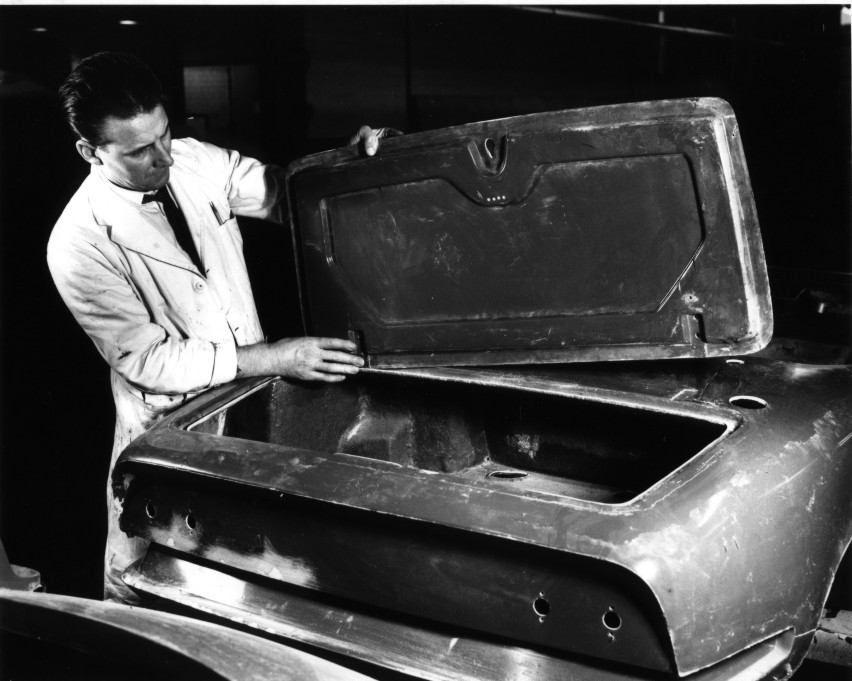

FIG 8

The Boot lid is check fitted to the body

FIG 9

The doors are checked for fit before going to the paint booth.

FIG 10

Then the headlamp pods are check fitted. Now the body is ready for final finishing and paint.