| The Europa Side - Twin Cam Baffled Oil Pan |

By Don Nester

Chapman Report – May 1979

The modification of the Twin Cam oil pan is really a requirement for all Europa (and Elan) Twin Cams. Colin Chapman in all his wisdom endowed the TC Europa with cornering capabilities which cause the oil pump to starve in right hand corners. This, as you would expect, is very hard on the engine’s inners.

The best and most expensive (about $500) correction to this problem is to dry sump the engine. The second best method is to add baffling to the oil pan. Modified pans may be purchased locally from Twin Cam Enterprises (out of business, try Dave Bean, RD or JAE – editor) for about $75.

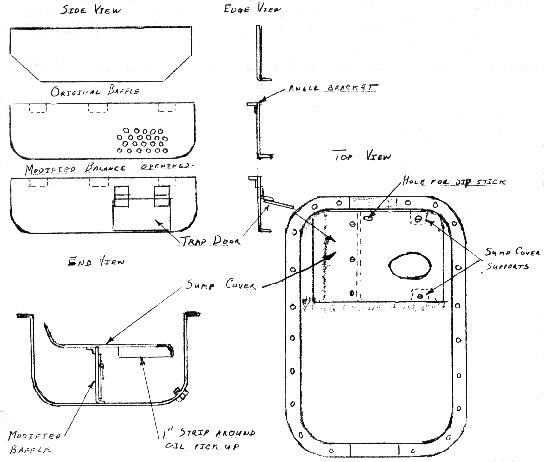

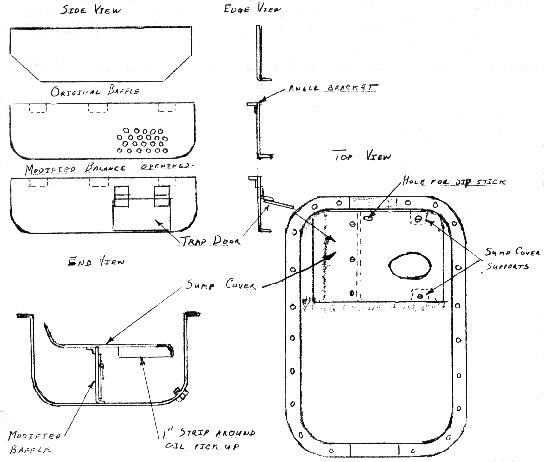

Being cheap and of the experimental type, I decided to modify my oil pan myself. Never having done this before, I carefully studied and sketched the Twin Cam Enterprises modified pan. Also, I studied what has been done with standard American cars (particularly high performance Chrysler products). I then sketched out my own solutions and began to worry if the baffling technique which I was to use would restrict the flow to the oil pump. After all, not being a hydraulic engineer, I questioned what the oil was really doing inside the sump. Well, after much concern and several sketches, I got out my welding torch and modified the sump. The sump has been back on my car for 8,000 miles, has caused no negative problems, and as far as I can tell, it has corrected the original problem of losing oil pressure on right hand turns. Here is my solution…

TWIN CAM OIL PAN BAFFLING

The single baffle in the center of the Twin Cam pan is insufficient to control oil starvation on right hand turns. The following modification is recommended to correct this problem.